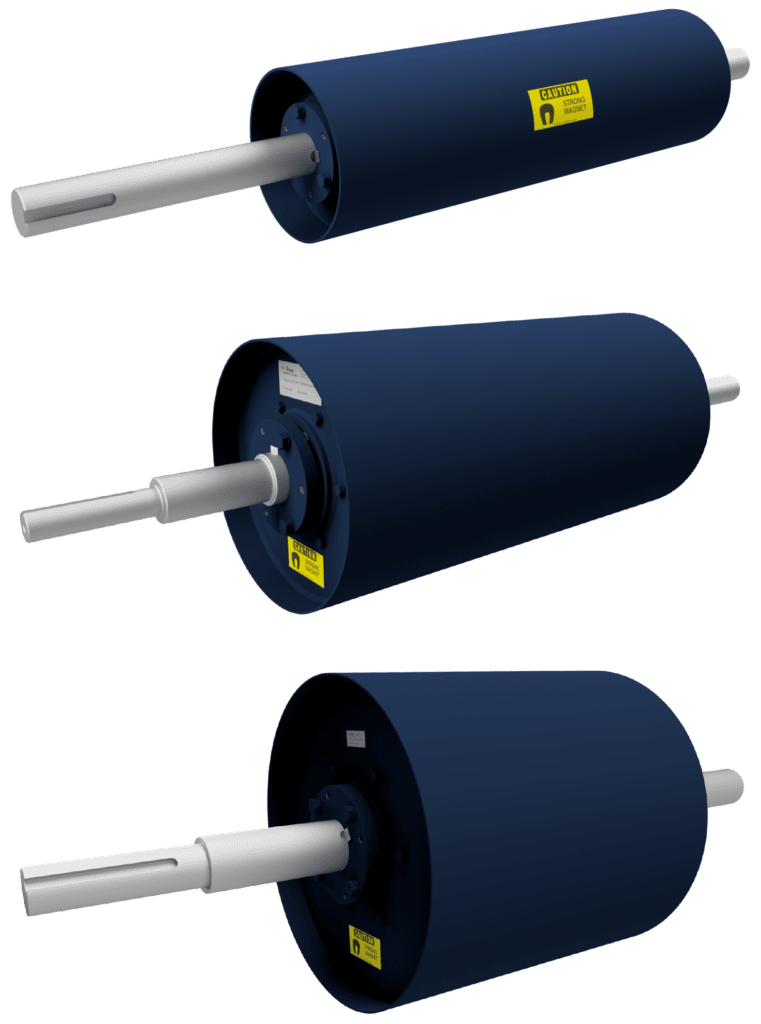

Magnetic Head Pulley

Dings company is unique in offering a series of three different magnetic head pulleys. This approach allows us to match the depth of the pulley’s magnetic field with the material burden-depth of your specific application.

Dings Magnetic Head Pulleys are permanent magnetic separators that operate as head pulleys on belt conveyors. These self-cleaning magnets remove tramp iron and purify material conveyed in bulk form. When material carried on a conveyor enters the magnetic field surrounding a pulley, pieces of ferrous metal in the material are attracted to the belt. Ferrous materials are magnetically held against the belt until carried to the underside of the pulley, where the belt takes them away from the magnetic field to be discharged. Nonmagnetic material falls away from the pulley at normal trajectory. Separation is automatic and continuous. A wide range of diameters, widths, shaft sizes are available.

Magnetic Head Pulley Operation

A Magnetic Head Pulley operates in the head pulley position of a belt conveyor. When material carried on the belt comes within range of the magnetic field, pieces of tramp iron or magnetic particles in the material are attracted to the belt. They’re held fast against the belt until carried to the underside of the pulley where the belt takes them away from the magnetic field to be discharged. Non-magnetic material falls away from the pulley in a normal trajectory. The separation action is automatic and continuous.

Standard Series Pulley Magnet

Our Standard Magnetic Head Pulley design has 6″, 8″, 12″, 15″, 18″, 20″ and 24″diameters available and is constructed with Grade VIII Ceramic Magnet Material – the highest grade available. The magnet material is encased by Type 304 non-magnetic stainless-steel and has welded construction.

FEATURES

- Lifetime Guarantee on magnetism

- Ceramic VIII ceramic magnet material – the highest grad

- No cost separation

- Corrosion-resistant weatherproof stainless-steel face

Heavy-Duty series pulley magnet

Our Heavy-Duty Magnetic Head Pulley model has larger magnetic poles which allows for a greater depth of magnetic field. The Heavy-Duty model has 12″, 15″, 18″, 20″ and 24″, 30″, 36″ and 42″ diameter options and is constructed with Grade VIII Ceramic Magnet Material – the highest grade available. The magnet material is encased by Type 304 non-magnetic flat stainless-steel shell and welded construction.

FEATURES

- Lifetime Guarantee on magnetism

- Ceramic VIII ceramic magnet material – the highest grad

- No cost separation

- Corrosion-resistant weatherproof stainless-steel face

DFC (Dings Flux Control) Ultra series pulley magnet

Our DFC (Dings Flux Control) Ultra Pulley Magnet model has the greatest depth of magnetic field. It is designed with our patented Dings Flux Control (DFC) Circuit, which eliminates leakage that other ‘conventional’ magnet circuits have. DFC allows the overall strength of the pulley’s magnetic field to be stronger and deeper. The DFC Ultra model comes in 12”, 15”, 18”, 20”, 24”, 30”, 36” and 42” diameters and is constructed with Grade VIII Ceramic Magnet Material – the highest grade available. The magnet material is encased by Type 304 non-magnetic flat stainless-steel shell and welded construction.

Dings Flux Control (DFC) Circuit Design

Dings Flux Control (DFC) Circuit Design was a breakthrough in the design of our permanent magnetic separators. It eliminates internal leakage between magnetic poles and improves separating performance.

Other “conventional” magnetic circuits contain air of filler material between the magnetic poles; this allow flux (magnetism) to leak out and be wasted. In the DFC design, blocking magnets are strategically positioned in the spaces to working force, which makes the magnet more efficient.

The overall strength of the magnet is improved in three ways:

- The magnetic field is stronger

- The magnetic field extends deeper

- The magnetic field pattern is more uniform

By using the DFC effectively, our magnetic solutions experts can manufacture any sized magnet that has just the right amount of magnetic power for your specific separation application – creating savings in weight and cost. This design is engineered and manufactured into our DFC Model of the Magnetic Head Pulley.

FEATURES

- Lifetime Guarantee on magnetism

- Patented Dings Flux Control (DFC) Circuit provided a stronger, deeper and more uniform magnetic field.

- Ceramic VIII ceramic magnet material – the highest grade

- No cost separation

- Corrosion-resistant weatherproof stainless-steel face

Options for All Models

Pulley Lagging

Pulley lagging is a covering applied to the outer surface of the magnetic head pulley to increase the coefficient of friction between the pulley and conveyor belt. Lagging is usually needed when a head pulley is used as a drive pulley on a long conveyor belt. Rubber lagging is the most popular type and it’s primarily used on the larger diameter pulleys.

Several benefits are gained by using pulley lagging. The lagging is manufactured with high quality materials designed to ensure maximum protection in tough applications. Conveyor belts last longer because they can operate at lower tension. The pulley shell life is extended due to the protection against abrasion from metal belt fasteners. Dings Co. Magnetic Group has many options of lagging available to meet your specific needs.

Vulcanized Lagging

Vulcanization is the curing of the rubber which results in increased rigidity and durability. Vulcanized rubber is less vulnerable to deformation. The vulcanized lagging has increased tensile strength which reduces the risk of physical damage. This type of lagging can withstand severe temperatures while working continuously.

Herringbone Grid

Herringbone groove lagging offers superior traction and is mainly used on drive pulleys. It displaces water and other liquids between the pulley face and the belt, therefore the direction of the grooves is very important. The center point always goes toward the direction of belt travel. The herringbone groove lagging is smooth and very robust.

Chevron Groove

Chevron groove lagging offers superior traction and is mainly used on drive pulleys. It displaces water and other liquids between the pulley face and the belt. Unlike the herringbone, the grooves meet at the pulley center so the liquid escapes in either direction.

Diamond Groove

Diamond groove lagging is sometimes referred to as double herringbone and is primarily used for reversing conveyor drive pulleys. The diamond groove has bi-directional pulley rotation, so that it can be used in either direction.

Rough Top Lagging

Rough Top Lagging gives excellent traction without cutting grooves. It is a 2-ply stretch duck fabric that has an irregular surface. The surface is comprised of a nubby rubber strip that is applied to the entire pulley surface to prevent slippage between the pulley and belt. It is used for wet, icy or dirty low-tension applications.

Tape (Safety Walk) Lagging

An abrasive tape that is adhered to the entire pulley surface to prevent slippage between the pulley and belt. This option provides traction when applied to slippery surfaces and is a reduced cost alternative to other lagging options.

Taper Lock Hubs & Bushings

A style/brand of bushing for fastening the shaft to the pulley.

XT Hubs & Bushings

A style/brand of bushing for fastening the shaft to the pulley.

Custom Designs

Our magnetic solutions experts can custom design any equipment to meet your specific application needs.