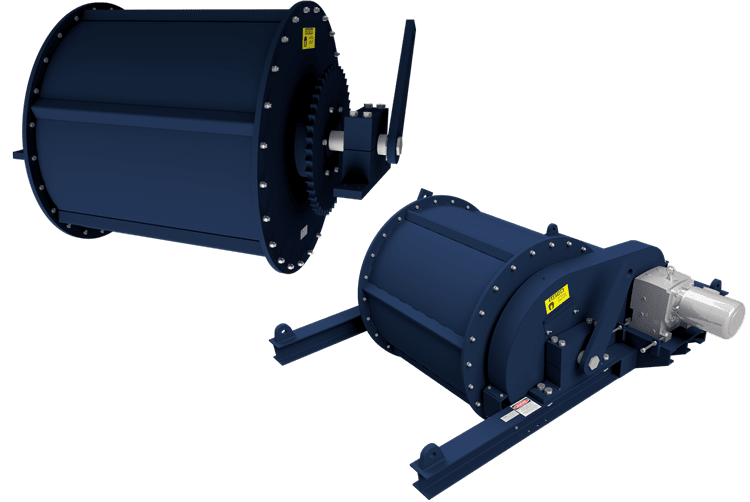

Deep Draw Drum Magnetic Separators

Dings Deep Draw Drums are self-cleaning, permanent magnets specifically designed for high-volume ferrous recovery (heavy-duty applications). Their design outperforms electric-powered magnetic separator models and always operates at top efficiency while maintaining a constant magnetic strength throughout the day. Its rugged construction is ideal for separating ferrous metal from material in shredded cars, scrap metals, municipal solid waste, wood waste, slag, recycling crushed ore and ash at mass burn-out plants. Deep Draw Magnetic Drums have heavier duty construction than permanent drums. The shell is protected with a thick manganese wear cover, which can withstand the punishment of continuous pounding by a steady flow of heavy objects. The Deep Draw Drum can be fed in multiple positions since the internal magnet assembly is adjustable.

FEATURES

- Guaranteed Lifetime Warranty on magnetism

- Patented Dings Flux Control (DFC) Circuit provides a stronger, deeper and more uniform magnetic field.

- Long-operating life with no energy consumption

- Rugged, dust-tight, weather-proof construction

- Heavy-duty self-aligned and sealed bearings

- Totally enclosed magnet assembly

- Magnet can be manually rotated counter-clockwise or clockwise to adjust magnetic arc position.

- Easy installation

- Replaceable heavy-duty manganese steel wear plate extends life of drum.

- Ceramic VIII magnetic material

OPTIONS

Frame & Drive Package

This package provides the means to drive the drum separator and includes a frame, drive assembly and chain guard for mounting structure which facilitates integration of the drum into an application.

Motion Sensor

This motion control safety sensor monitors drum rotation and alerts the operator if drum stops turning.

Various Cleats

Stainless-steel and various cleat designs are available based on application requirements.

Custom Designs

Our magnetic solutions experts can custom design any equipment to meet your specific application needs.

Why Choose Permanent Deep Draw Drums?

The Dings permanent deep draw drum magnetic separator outperforms electro models by always operating at top efficiency and maintaining a constant gauss or magnetic strength throughout the day.

Electro drum magnets lose some magnetism and separating power as the coil heats up during operation. This reduction in magnetism from startup to the operating temperature reached several hours later can be as great as 30%. The result is a drop-off in metal recovery.

The Deep Draw Drum Permanent Magnet Separator emits a very powerful, uniform magnetic field. It costs nothing to operate and does not require a rectifier, generator, switch gear or wiring. There are no magnet coils to burn out.

Deep Draw Magnetic Drum Feed Arrangements

The Deep Draw Drum can be fed in any position since the internal magnet assembly is adjustable. The drum is easy to install on general contractor I beams. After mounting, the magnet arc is adjusted to match the feed location. Feed position can affect the purity of the recovered metal contaminants. In the top feed position, for instance, ferrous attracted to the drum can entrap nonmetallic material against the drum shell, with both being deposited on the ferrous side of the splitter.

Up & Over

Ferrous is lifted out of the burden and carried up and over the magnet while the nonferrous material drops off the feeder. This feed arrangement minimizes the amount of entrapped nonferrous material and produces a clean ferrous product.

Down & Under

This arrangement has the shortest and most direct transfer area for the ferrous and is often recommended for material with large and heavy pieces of ferrous.

Top Feed

Often used with ferrous material that is weakly magnetic or with feed that contains non-ferrous pieces too large to pass through a reasonable gap.